DKA are committed to developing design solutions to improve the built environment. In partnership with clients, consultants, contractors, local authorities and other participants in the development process, we seek to control the impact of our projects on the natural environment and local communities. We have been delivering highly sustainable buildings for over 25 years, reducing the energy consumptions of our clients’ buildings and improving the experience of the building users.

Passivhaus is becoming an aspiration for many of our clients, particularly in the public sector for new school projects. The combination of a ‘fabric first’ approach combined with low energy bills makes this an attractive proposition, and directly helps tackle the UK Governments Carbon Reduction targets and addresses the Climate Emergency declared by many local authorities.

Before embarking on a Passivhaus project you need to understand the methodology, the terminology and the outcomes. This post explains these principles along with the skills you require from your professional team. We can help you on your journey.

What is a Passivhaus?

Methodology

Passivhaus is a voluntary quality assured building performance standard and methodology that provides buildings with a high level of occupant comfort while reducing their energy use and carbon emissions. Passivhaus projects are built with meticulous attention to detail following a rigorous design process according to principles developed by the Passivhaus Institute in Germany, and can be certified through an exacting Quality Assurance process.

Passivhaus is not just a domestic standard, and the UK has seen a rise in the number of commercial buildings and public sector buildings being designed to this method.

Achieving the Passivhaus Standard in the UK typically involves:

- Accurate design modelling using the Passive House Planning Package (PHPP)

- Very high levels of insulation far in excess of UK Building Regulations

- Extremely high-performance windows with insulated frames

- Building orientation optimised for beneficial solar gain

- An extremely airtight building fabric far in excess of UK Building Regulations

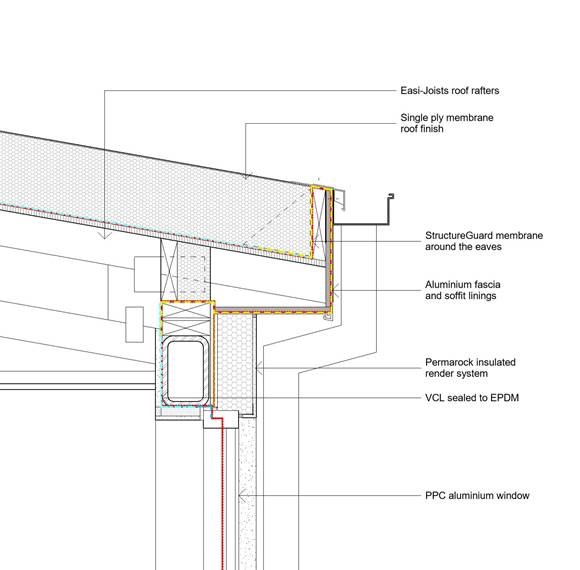

- ‘Thermal bridge free’ construction focusing on junctions and interfaces

- A mechanical ventilation system with highly efficient heat recovery

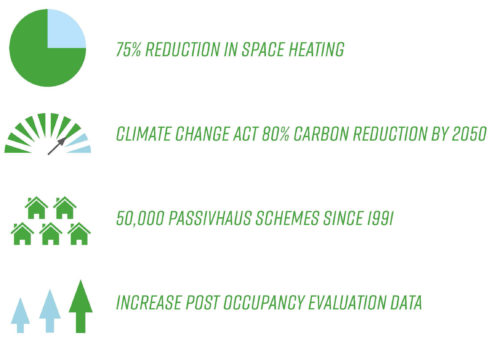

Building Performance

Passivhaus buildings achieve a 75% reduction in space heating requirements, compared to standard practice for UK new build. The Passivhaus standard therefore gives a robust method to help the industry achieve the 80% carbon reductions that are set as a legislative target for the UK Government. Passivhaus also applies to retrofit projects, achieving similar savings in space heating requirements.

The first houses built to Passivhaus standard were completed in 1991, and since then over 50,000 houses, schools and offices have been constructed to the standard in Europe, USA and many other parts of the world. There has been extensive monitoring of Passivhaus buildings which has demonstrated conclusively that they are performing to standard. This is crucial, given that the discrepancy between design aspiration and as-built performance for many new buildings in the UK can be as much as 50-100%.

Internal Environment and Comfort

Passivhaus buildings are praised for the high level of comfort they offer throughout the whole year, not only during cold seasons.

Good indoor air quality is an essential requirement, with the ventilation system providing 30m3 of fresh air every hour, for every person in the building.

Not only must the building fabric be draught-free, but the standard requires that the internal surface temperatures vary little from indoor air temperatures, avoiding cold spots even in the face of extreme outdoor temperatures.

In addition, the reduced air leakage, combined with high levels of insulation and efficient glazing have a knock-on effect to the building’s acoustic performance, which can exceed the standards required by the Building Regulations.

Construction

To achieve all these standards, the construction process must be rigorous and with meticulous attention to detail. This relies on close coordination of the junctions between different materials and a clear understanding of the responsibility of different trades.

Materials must also be of high quality, robust and long lasting. This places a large responsibility onto the contractor and their supply chain to supply the correct products and fit them according to the design performance requirements.

The Passivhaus standard advises that the site team in particular are key to this and should ideally have prior knowledge of this method of building.

Cost

Like other sustainable methodologies, any cost uplift is minimised if designed from first principles. Passivhaus must be understood and integrated into the design approach from the outset in order to achieve an economic solution.

On average, a Passivhaus might cost 5 to 10% more in capital terms. However, these buildings do not require heating and cooling systems on conventional scales, meaning that the operational costs are significantly reduced over the life span of the building – particularly attractive for an owner occupier.

This long-term energy saving makes Passivhaus buildings more cost effective over the long term than a conventional building.

How can DKA Help?

We are looking for partners to expand our sustainability experience, particularly local authorities and main contractors looking to develop Passivhaus schemes. What makes DKA suitable?

- Over 25 years experience of delivering highly sustainable projects for public and private sector

- Extensive experience of designing educational environments from nursery to university level, along with a particular expertise in designing for students with Special Educational Needs

- DKA have a Certified Passivhaus Designer and more staff undergoing the training

- DKA are members of the Passivhaus Trust, helping to promote the standard in the UK and with access to the latest technical information and experience

- DKA regularly act as lead consultant, often with a role to coordinate specialist MEP and other engineering elements

- DKA have a number of Certified Autodesk® Professionals and more than ten years’ experience collaborating on major projects with BIM requirements for private clients, local authorities and contractors

- Our success lies in the quality of our relationships. We treat our clients, consultants and contractors as partners, and are delighted that over 70% of clients choose to work with us again

Meet our sustainability team here: Fabien Coupat

If you like to contact us to discuss how we can help you on your next Passivhaus project, you can do so here.